| Anmol Chemicals is the pioneer manufacturers of Sodium Lactate, Pharmaceutical Excipients Fragrance Food & Flavor chemicals in India. We offer Halal and Kosher Sodium Lactate made in an ISO9001, ISO22000 (FSSC22000) cGMP and GLP certified facility. Our group has several manufacturing facilities spread across the world, supported by toll manufacturers and representatives in UAE, Europe, USA, China and has several associated manufacturing facilities spread across India. All the Information on Physics, Chemistry, Applications, Uses and Technology on Manufacture of Sodium Lactate is in these pages. |

| The units have one or more of the certifications like FDA GMP, ISO 9001, ISO 22000, HACCP, REACH, Kosher & Halal |

Sodium Lactate USP FCC Food Grade Manufacturers

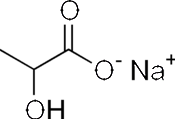

Sodium Lactate CAS Number 72-17-3, EINECS EC Number 200-772-0, Molecular Weight 112.06, Molecular Formula: C3H5NaO3

SDS GHS MSDS Sheet of Sodium Lactate

Sodium Lactate

USP FCC

Food Grade

English Sodium Lactate-Sodium-Lactobionate-Lactic Acid-Lactobionic Acid

Arabic لاكتات الصوديوم - الصوديوم - لاكتوبيونات - حمض اللاكتيك - حمض اللاكتوبيونيك

Spanish Lactato de sodio-Lactobionato de sodio-Ácido láctico-Ácido lactobiónico

Portuguese Fabricante de lactato de sódio-lactobionato de sódio-ácido láctico-ácido lactobiônico

French Lactate de sodium-lactobionate de sodium-acide lactique-acide lactobionique

Dutch Natriumlactaat-Natrium Lactobionaat-Melkzuur-Lactobionzuur

German Natriumlactat-Natrium-Lactobionat-Milchsäure-Lactobionsäure

Italian Sodio Lattato-Sodio-Lattobionato-Acido Lattico-Acido Lattobionico

Specifications of Sodium Lactate Solution USP Grade

Sodium Lactate Solution is an aqueous solution containing not less than 50.0 percent, by weight, of monosodium lactate. It contains not less than 98.0 percent and not more than 102.0 percent of the labeled amount of C3H5NaO3.

Identification: It responds to the tests for Sodium and for Lactate.

pH: between 5.0 and 9.0.

Chloride: A portion, equivalent to 1 g of sodium lactate, shows no more chloride than corresponds to 0.7 mL of 0.020 N hydrochloric acid (0.05%).

Sulfate: To 10 mL of a solution (1 in 100) add 2 drops of hydrochloric acid and 1 mL of barium chloride TS: no turbidity is produced.

Heavy metals: Dilute a quantity of Solution, equivalent to 2.0 g of sodium lactate, with 1 N acetic acid to 25 mL: the limit is 0.001%.

Sugars: To 10 mL of hot alkaline cupric tartrate TS add 5 drops of Solution: no red precipitate is formed.

Limit of citrate, oxalate, phosphate, or tartrate: Dilute 5 mL with recently boiled and cooled water to 50 mL. To 4 mL of this solution add 6 N ammonium

hydroxide or 3 N hydrochloric acid, if necessary, to bring the pH to between 7.3 and 7.7. Add 1 mL of calcium chloride TS, and heat in a boiling water bath for 5

minutes: the solution remains clear.

Limit of methanol and methyl esters:

Potassium permanganate and phosphoric acid solution— Dissolve 3 g of potassium permanganate in a mixture of 15 mL of phosphoric acid and 70 mL of water. Dilute with

water to 100 mL.

Oxalic acid and sulfuric acid solution— Cautiously add 50 mL of sulfuric acid to 50 mL of water, mix, cool, add 5 g of oxalic acid, and mix to dissolve.

Standard preparation— Prepare a solution containing 10.0 mg of methanol in 100 mL of dilute alcohol (1 in 10).

Test preparation— Place 40.0 g in a glass-stoppered, round-bottom flask, add 10 mL of water, and add cautiously 30 mL of 5 N potassium hydroxide. Connect a condenser to

the flask, and steam-distill, collecting the distillate in a suitable 100-mL graduated vessel containing 10 mL of alcohol. Continue the distillation until the volume in

the receiver reaches approximately 95 mL, and dilute the distillate with water to 100.0 mL.

Procedure— Transfer 10.0 mL each of the Standard preparation and the Test preparation to 25-mL volumetric flasks, to each add 5.0 mL of Potassium permanganate and

phosphoric acid solution, and mix. After 15 minutes, to each add 2.0 mL of Oxalic acid and sulfuric acid solution, stir with a glass rod until the solution is colorless,

add 5.0 mL of fuchsin-sulfurous acid TS, and dilute with water to volume. After 2 hours, concomitantly determine the absorbances of both solutions in 1-cm cells at the

wavelength of maximum absorbance at about 575 nm, with a suitable spectrophotometer, using water as the blank: the absorbance of the solution from the Test preparation

is not greater than that from the Standard preparation (0.025%).

Assay: Weigh accurately into a suitable flask a volume of Solution, equivalent to about 300 mg of sodium lactate, add 60 mL of a 1 in 5 mixture of acetic anhydride

in glacial acetic acid, mix, and allow to stand for 20 minutes. Titrate with 0.1 N perchloric acid VS, determining the endpoint potentiometrically. Perform a blank

determination, and make any necessary correction. Each mL of 0.1 N perchloric acid is equivalent to 11.21 mg of C3H5NaO3.

Specifications of Sodium Lactate Solution FCC Food Grade

2-Hydroxypropanoic Acid, Monosodium Salt

DESCRIPTION

Sodium Lactate Solution occurs as a clear, colorless or practically colorless, slightly viscous liquid that is odorless or has a slight, not unpleasant odor. It is

miscible with water. It is normally available in solutions with concentrations ranging from 60% to about 80%, by weight.

Function: Emulsifier; flavor enhancer; flavoring agent or adjuvant; humectant; pH control agent.

REQUIREMENTS

Indicate the content, by weight, of sodium lactate (C3H5NaO3).

Identification: A sample gives positive tests for Sodium and for Lactate.

Assay: Not less than 50.0%, by weight, and not less than 98.0% and not more than 102.0%, by weight, of the labeled amount of C3H5NaO3.

Chloride: Not more than 0.05%.

Citrate, Oxalate, Phosphate, or Tartrate: Passes test.

Cyanide: Not more than 0.5 mg/kg.

Lead: Not more than 2 mg/kg.

Methanol and Methyl Esters: Not more than 0.025%.

pH: Between 5.0 and 9.0.

Sugars: Passes test.

Sulfate: Not more than 0.005%.

TESTS

Assay: Transfer a volume of sample, equivalent to about 300 mg of sodium lactate and accurately weighed, into a suitable flask. Add 60 mL of 1:5 acetic

anhydride, glacial acetic acid, mix, and allow to stand for 20 min. Titrate with 0.1 N perchloric acid in glacial acetic acid, determining the endpoint potentiometrically.

Caution: Handle perchloric acid in an appropriate fume hood.

Perform a blank determination (see General Provisions), and make any necessary correction. Each milliliter of 0.1 N perchloric acid is equivalent to 11.21 mg of C3H5NaO3.

Chloride: Determine as directed in the Chloride Limit Test under Chloride and Sulfate Limit Tests. Any turbidity produced by a quantity of a sample solution

containing the equivalent of 40 mg of sodium lactate does not exceed that shown in a control containing 20 g of chloride (Cl) ion.

Citrate, Oxalate, Phosphate, or Tartrate: Dilute 5 mL of sample to 50 mL with recently boiled and cooled water. Add 6 N ammonium hydroxide or 3 N hydrochloric

acid to 4 mL of this solution, if necessary, to bring the pH to between 7.3 and 7.7. Add 1 mL of calcium chloride TS, and heat in a boiling water bath for 5 min. The

solution remains clear.

Cyanide: (Caution: Because of the extremely poisonous nature of potassium cyanide, conduct this test in a fume hood, and exercise great care to prevent skin

contact and the inhalation of particles or vapors of solutions of the material. Under no conditions pipet solutions by mouth.)

p-Phenylenediamine–Pyridine Mixed Reagent: Dissolve 200 mg of p-phenylenediamine hydrochloride in 100 mL of water, warming to aid dissolution. Cool, allow the solids to

settle, and save the supernatant liquid to make the mixed reagent. Dissolve 128 mL of pyridine in 365 mL of water, add 10 mL of hydrochloric acid, and mix. To prepare

the mixed reagent, mix 30 mL of the p-phenylenediamine supernatant liquid with all of the pyridine solution, and allow to stand for 24 h before using. The mixed reagent

is stable for about 3 weeks when stored in an amber bottle.

Cyanide Standard Solution: Dissolve 250 mg of potassium cyanide, accurately weighed, in 10 mL of 0.1 N sodium hydroxide contained in a 100 mL volumetric flask,

dilute to volume with 0.1 N sodium hydroxide, and mix. Transfer a 10-mL aliquot into a 1000-mL volumetric flask, dilute to volume with 0.1 N sodium hydroxide, and mix.

Each milliliter of this solution contains 10 g of cyanide.

Sample Solution: Transfer a quantity of sample, equivalent to 20.0 g of sodium lactate and accurately weighed, into a 100-mL volumetric flask, dilute to volume

with water, and mix.

Procedure: Pipet a 10-mL aliquot of the Sample Solution into a 50-mL beaker. Pipet 0.1 mL of the Cyanide Standard Solution into a second 50-mL beaker, and add 10 mL of

water. Place the beakers in an ice bath, and adjust the pH to between 9 and 10 with 20% sodium hydroxide, stirring slowly and adding the reagent slowly to avoid

overheating. Allow the solutions to stand for 3 min, and then slowly add 10% phosphoric acid to a pH between 5 and 6, measured with a pH meter.

Transfer the solutions into 100-mL separators containing 25 mL of cold water, and rinse the beakers and pH meter electrodes with a few milliliters of cold water,

collecting the washings in the respective separator. Add 2 mL of bromine TS, stopper, and mix. Add 2 mL of 2% sodium arsenite solution, stopper, and mix. Add 10 mL of

n-butanol to the clear solutions, stopper, and mix. Finally, add 5 mL of p-Phenylenediamine–Pyridine Mixed Reagent, mix, and allow to stand for 15 min. Remove and

discard the aqueous phases, and filter the alcohol phases into 1-cm cells. The absorbance of the solution from the Sample Solution, determined at 480 nm with a suitable

spectrophotometer, is no greater than that from the Cyanide Standard Solution.

Lead: Determine as directed in the Flame Atomic Absorption Spectrophotometric Method under Lead Limit Test, using a 5-g sample.

Methanol and Methyl Esters:

Potassium Permanganate and Phosphoric Acid Solution: Dissolve 3 g of potassium permanganate in a mixture of 15 mL of phosphoric acid and 70 mL of water. Dilute to 100

mL with water.

Oxalic Acid and Sulfuric Acid Solution: Cautiously add 50 mL of sulfuric acid to 50 mL of water, mix, cool, add 5 g of oxalic acid, and mix to dissolve.

Standard Preparation: Prepare a solution containing 10.0 mg of methanol in a 100-mL volumetric flask, dilute to volume with 1:10 alcohol, and mix.

Test Preparation: Place 40.0 g of sample in a glass-stoppered, round-bottom flask, add 10 mL of water, and cautiously add 30 mL of 5 N potassium hydroxide.

Connect a condenser to the flask, and steam-distill, collecting the distillate in a suitable 100-mL graduated vessel containing 10 mL of alcohol. Continue the

distillation until the volume in the receiver reaches approximately 95 mL, and dilute the distillate to 100.0 mL with water.

Procedure: Transfer 10.0 mL each of the Standard Preparation and the Test Preparation to 25-mL volumetric flasks. Add 5.0 mL of Potassium Permanganate and

Phosphoric Acid Solution to each, and mix. After 15 min, add 2.0 mL of Oxalic Acid and Sulfuric Acid Solution to each, stir with a glass rod until the solutions are

colorless, add 5.0 mL of fuchsin–sulfurous acid TS, dilute to volume with water, and mix. After 2 h, using a suitable spectrophotometer, concomitantly determine the

absorbances of both solutions in 1-cm cells at the wavelength of maximum absorbance at about 575 nm, using water as the blank. The absorbance of the solution from the

Test Preparation is not greater than that from the Standard Preparation.

pH: Determine as directed under pH Determination.

Sugars: Add 5 drops of sample to 10 mL of hot alkaline cupric tartrate TS. No red precipitate forms.

Sulfate: Determine as directed in the Sulfate Limit Test under Chloride and Sulfate Limit Tests. Any turbidity produced by a quantity of the sample solution

containing the equivalent of 4.0 g of sodium lactate does not exceed that shown in a control solution containing 200 g of sulfate (SO4) ion.

We also offer Lactic Acid.

Sodium Lactate Manufacturers:

Anmol Chemicals

S-8, SARIFA MANSION, 2ND FLANK ROAD, CHINCHBUNDER, MUMBAI 400009, INDIA

TEL: (OFFICE) 91-22-23770100, 23726950, 23774610, 23723564. FAX: 91-22-23728264

e-mail: anmolc@mtnl.net.in

Exports to USA, Canada, UAE, Dubai, South Africa, Tanzania, Kenya, Nigeria, Egypt, Uganda, Turkey, Mexico, Brazil, Chile, Argentina, Europe Netherlands, Italy, Spain, Germany, Portugal, France, Malaysia, Indonesia, Thailand, Korea, Russia, Norway, Japan, etc.

Copyright and Usual Disclaimer is Applicable. 17 February, 2022